MGP pumps

SCIENTIFIC PRODUCTION ENTERPRISE ELEKTROKONTAKTNYE TEKHNOLOGII LTD MAGNETIC HYDRODYNAMICS

SCIENTIFIC PRODUCTION ENTERPRISE ELEKTROKONTAKTNYE TEKHNOLOGII LTD MAGNETIC HYDRODYNAMICS

develops, makes and delivers magnetic hydrodynamic pumps

Induction MGP PUMPS alternating current, heat-resistant, without water and gas cooling, both immerse, and open type.

- Systems of emergency and technological drain of the melted metals from the capacities, regulated outcome..

- Systems of transportation of the melted metals and alloys at flood in moulds and receiving of the cast.

TECHNICAL CHARACTERISTICS OF MGP:

- a working body – alkaline metals, zinc, tin, lead and their alloys, alloys on the basis of aluminium.

- temperature of alloy – to 700°С.

- productivity of one MGP – to 300 m3/hours

- pressure on an exit of MGP – to 20×105 N/sq.m.

- a power feed of MGP from a standard source of adjustable power of industrial frequency or from diod converter.

ADVANTAGES of MGP:

- there are no rotating and rubbing details.

- there is no external cooling.

- smooth adjustment of productivity in a wide range.

- simplicity of operation and service.

- reliability and safety in work.

PRINCIPLE OF ACTION MGP:

The principle of action of induction MGP is based on contactless impact of the “running” magnetic field created by flat and linear inductors, on liquid metal in the pump channel..

As an example we provide characteristics of a number of the pumps working at plants of the CIS.

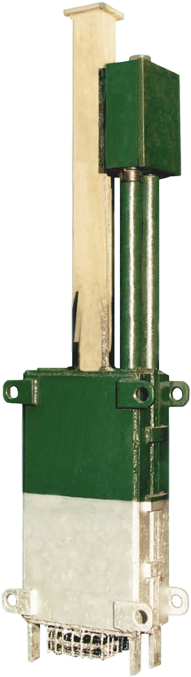

In drawing it is shown AMN-11ATs (base model) after two years of operation.

| Основные параметры | АМН-7 | АМН-11АЦ | АМН-13Ц | АМН-14С | АМН-15А |

| Рабочее тело | цинк | Алюмоцинк | Цинк | свинец | алюминий |

| Температура | 460°С | 710°С | 460°С | 550°С | 740°С |

| Расход | 410 т/час | 380 т/час | 160 т/час | 200 т/час | 1 кг/сек |

| Высота подъема расплава или давление | 3,8м | 3,8м | 2,7м | 4,5 м | до 20´105н/м2 |

| Ток фазы | 420 А | 220 А | 220 А | 380 А | 50 А |

| Кол-во фаз | 3 | 3 | 3 | 3 | 3 |

| Частота | 50 Гц | 50 Гц | 50 Гц | 50 Гц | 50 Гц |

| Напряжение | 220В | 300 В | 220В | 350В | 50-120В |

| Масса | 2,5т | 1,8т | 1,2т | 2,5 т | 90 кг |

| Габариты без выходного патрубка | 1,5 x 0,345 x 0,525 м | 1,0 x 0,345 x 0,525 м | 0,8 x 0,345 x 0,525 м | 1,5 x 0,345 x 0,525 м | Ф 0,27 x 0,583 м |

OUR laboratory makes MGP pumps with the parametres necessary for the specific customer. According to Customer specification the pump can be additionally equipped with a source of adjustable tension. Development of the cell equipment can be executed if necessary.

We offer you cooperation in the field of delivery of MGP systems for all objects of application interesting you.

Main activities of MGP technology

The main activity of MGP equipment for many years is design and creation of high-temperature induction pumps for transfer of alloys of non-ferrous metals. Feature of pumps developed by our enterprise is their permanent ability to work without external cooling in high-temperature and hostile environment.

Originally this technology was developed for pumping of liquid sodium in contours of cooling of nuclear reactors on fast neutrons. In particular, the pump AMN 3500 was designed and constructed for work in the main contours of the BN 600 reactor. Productivity of this pump is 1 M3./second at temperature of sodium of 600 C.

Use of high-temperature pumps for needs of nuclear power is the most natural scope of this technologies

The video film showing operation of the pumps AMN-11ATs and AMN-13Ts in industrial conditions.